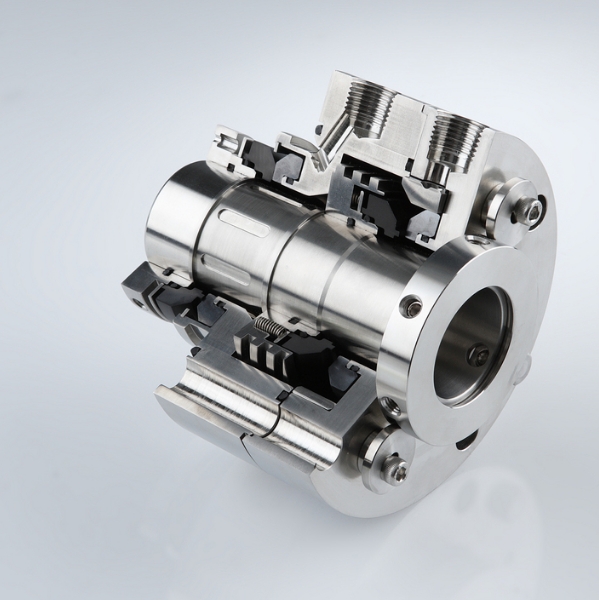

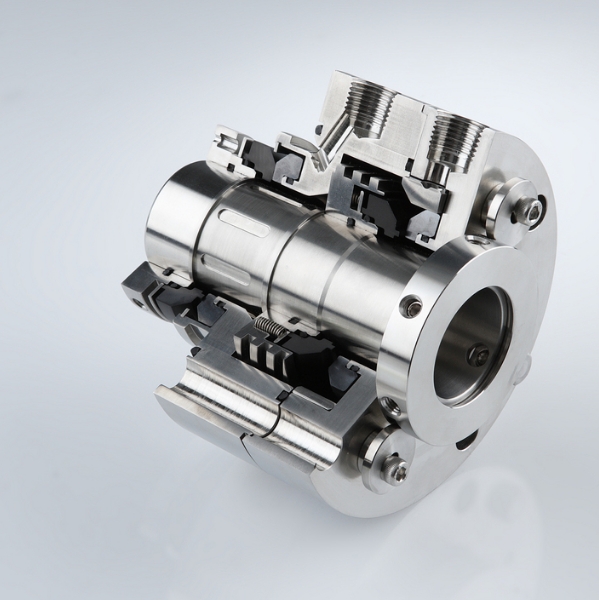

In recent years, with the continuous development of the aerospace industry, the demand for aircraft reliability has increased. In order to ensure flight safety and improve flight efficiency, a new type of multi-spring mechanical sealing technology has been widely applied in the aerospace industry.Traditional mechanical sealing technology has some issues in high-speed rotating equipment, such as material wear and leakage. However, multi-spring mechanical sealing technology, by introducing multiple springs, can better adapt to the working environment of high-speed rotating equipment, improving sealing performance and reliability.The advantages of multi-spring mechanical sealing technology are mainly reflected in the following aspects. Firstly, it effectively reduces leakage issues. By using multiple springs, it can better adapt to the working conditions of the equipment, improving sealing performance and reducing the risk of leakage. This is particularly important in the aerospace industry, as leakage during flight can lead to serious safety accidents.Secondly, Multiple Spring Mechanical Seal technology has a longer service life. Traditional mechanical sealing technology is prone to wear and corrosion from high-speed rotating equipment, resulting in a shorter service life. However, multi-spring mechanical sealing technology, with its design of multiple springs, can share the workload of the sealing material, extending its service life.Furthermore, multi-spring mechanical sealing technology can improve the efficiency of equipment. Traditional mechanical sealing technology in high-speed rotating equipment tends to generate friction and heat, leading to energy loss. However, multi-spring mechanical sealing technology can reduce friction and heat generation, improving equipment efficiency and reducing energy consumption.The application of multi-spring mechanical sealing technology has achieved significant results in the aerospace industry. For example, in the turbine cover sealing of aircraft engines, multi-spring mechanical sealing technology can effectively reduce leakage issues, improving engine reliability and safety. In the propulsion system of spacecraft, multi-spring mechanical sealing technology can improve sealing performance, reduce propellant leakage,O Ring Mechanical Seals and ensure the normal operation of the spacecraft. In conclusion, the application of multi-spring mechanical sealing technology brings important technological breakthroughs to the aerospace industry. It not only improves aircraft reliability and safety but also enhances flight efficiency and reduces energy consumption. In the future, with the continuous development of technology,Mechanical Seals multi-spring mechanical sealing technology is expected to play a greater role in the aerospace field.